ML-Powered Assembly Line Optimization

This allows for quick identification and resolution of bottlenecks, leading to notable improvements in operational efficiency.

Scope

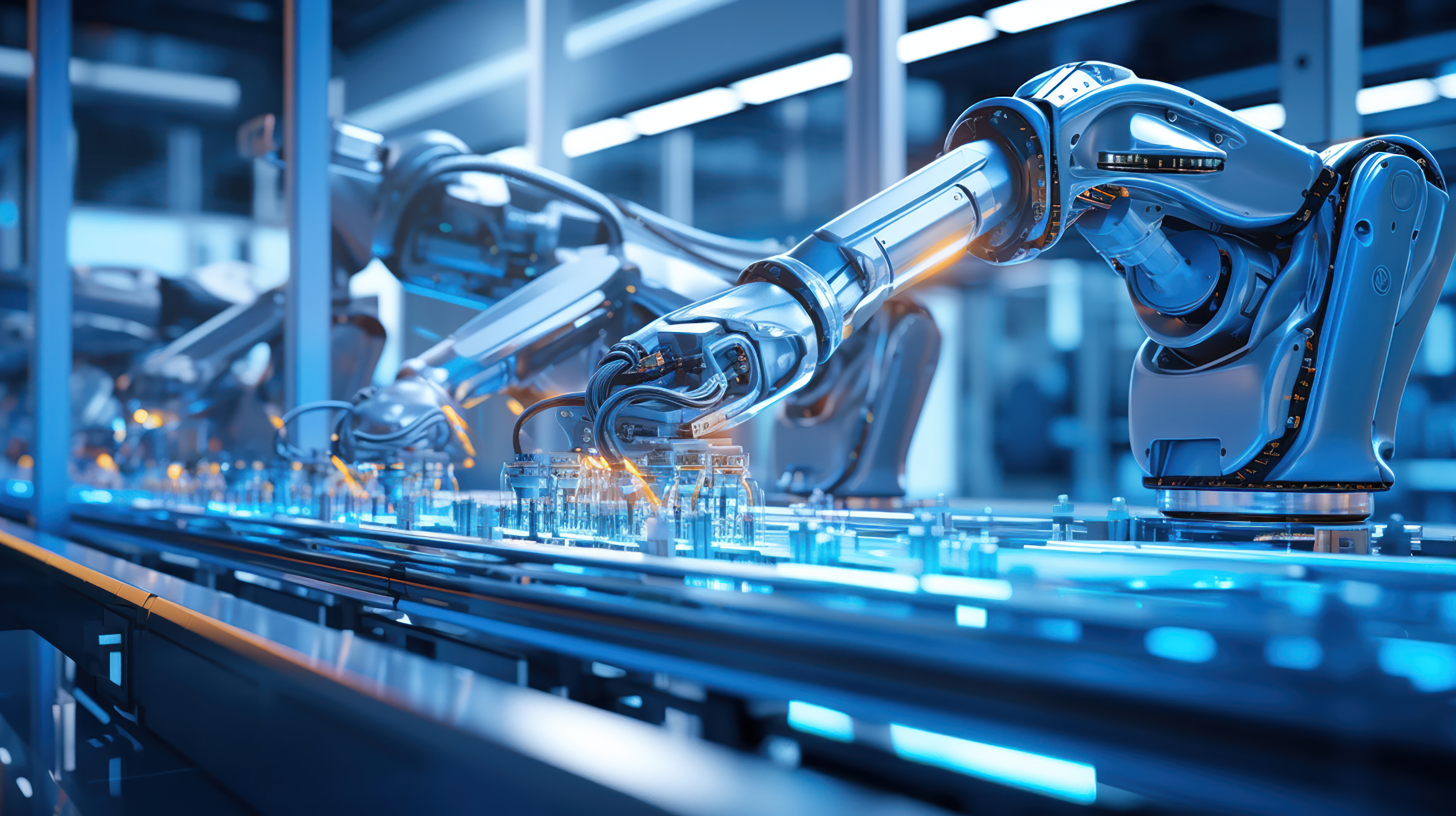

Tech Mahindra sought to address longstanding inefficiencies in assembly line operations by implementing an advanced solution to enhance productivity and reduce the cost of quality. Their goal was to optimize the assembly process through real-time monitoring and analysis, identifying hidden bottlenecks, and minimizing variations in cycle times.

To meet these goals, Tech Mahindra aimed to develop a solution utilizing AI-powered video analytics for real-time, precise monitoring of each workstation’s performance. This solution needed to manage substantial data volumes, support root cause analysis using archived video footage, and provide instant alerts to enable prompt corrective actions. The primary objective was to boost assembly line efficiency, strengthen quality control, and achieve notable improvements in productivity while lowering operational expenses.

Our Contribution

In the development and deployment of LineSense, SoftmaxAI played a crucial role by providing advanced machine learning (ML) expertise and implementing a robust MLOps pipeline to ensure the solution’s effectiveness and efficiency. Our team collaborated closely with Tech Mahindra to integrate complex ML capabilities into the project. We established a comprehensive MLOps framework to manage and track experiments, training, data annotation, augmentation, and inferencing processes.

Using NVIDIA Jetson devices, we enabled local, on-premise inferencing to manage real-time data processing and analysis. Our core technology stack included a robust cloud-based machine learning platform for scalable and efficient model training and deployment, complemented by the Meta SlowFast model for accurate human action recognition during engine assembly procedures. By leveraging these technologies and our ML expertise, SoftmaxAI significantly contributed to building and refining the LineSense solution, enhancing its ability to optimize assembly line operations and improve overall productivity and quality.